HZS150/180 Batch Plant

- about this model

- technical data

- brochure download

| DEMONSTRATION WITH PHOTOS | ||||

|

|

|

||

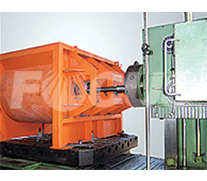

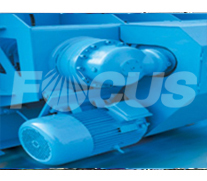

| Mainframe processing advanced tech. handles multi-sealed shaft-end. | Automatic lubricating system, fixed point, time and quantity, easy op. | Planetary reducer, efficient transmission, compact structure | ||

|

|

|

||

| Discharging door adopts top brand hydraulic system to drive and has adjustable opening. It’s equipped with manual pump in case of emergency. |

|

Main tower dust-removal device, excellent environmental protection, friendly and anti-noise designed. | ||

|

|

|

||

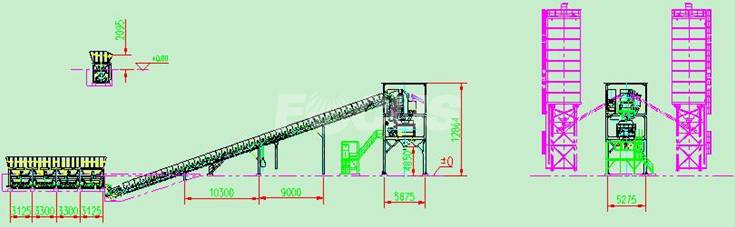

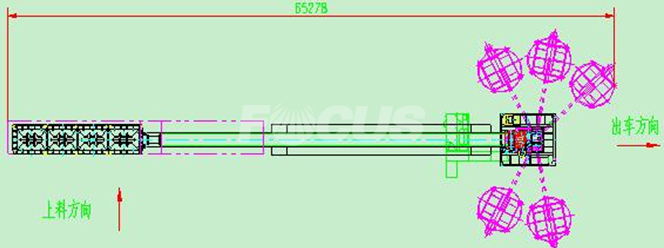

| Belt conveyor environmental device. All powder materials are in closed state during delivering, measuring, and putting-in. Main tower is equipped dust-exhauster/remover and wind blower while belt conveyor is with outer package and charge chute. | Low-position batcher | High-position batcher | ||

| Each and every aggregate is weighed individually or accumulatively, and the weighing accuracy is guaranteed. The accuracy of aggregates proportional ratio is realized through computer control system, which automatically re-feeds the aggregates if there is shortage of weight, warns if there is overweight. | ||||

|

|

|

||

| Automatic combined with manual control, easy operation; Dynamic display of the production process, and monitoring in real time; Saving of the data of production perimeters in the computer, printing of the daily, monthly, and yearly statistic reports of production; The operators, with the assistance of safety monitoring system, will know and monitor the running situations of the mixing plant in the control room; The control room, which is made of colorful shaped steel plates, is spacious, anti-noise and heat insulated, it guarantees the working temperature of the electrical components, also improves the working comfortability. | Twin-shaft mixer has the strong mixing ability with uniform mixing and high production output, reliable shaft end tech+high wear-resisting lining plate, paddles, arms and blade, long service life; Double discharging way, hydraulic gate assembly can be adjusted accordingly. | |||

|

|

|

||

Click to enlarge the form

Please note:

1. The total power doesn't include the power of cement silo and screw;

2. Non-standard design could be made according to clients' demand;

3. The above-mentioned data could be changed due to technical&design upgrade, please check

the updated configuration when purchasing.

| Main technical data | |

|---|---|

| Type | HZS180 |

| Productivity in theory | 180m³/h |

| Mixer | JS3000 |

| Total power | 205KW |

| Maximum aggregate diameter | 80mm |

| Aggregate feeding method | Conveyor belt |

| Aggregate bins volume | 4x18m³ |

| Aggregate weighing | 2x4000kg ±2% |

| Cement weighing | 1800kg ±1% |

| Fly-ash weighing | 800kg ±1% |

| Water weighing | 800kg ±1% |

| Additive weighing | 50kg ±1% |

| Discharging height | 3.8m |

|

Overall dimension(during operating) (LXWXH) |

58.5mX7mX12.9m |

| Total weight | 77T |

| Control | Fully automatic central plus manual control |

| Cement silo(optional) | On request |

| Cement screw(optional) | On request |

Please note:

1. The total power doesn't include the power of cement silo and screw;

2. Non-standard design could be made according to clients' demand;

3. The above-mentioned data could be changed due to technical&design upgrade, please check

the updated configuration when purchasing.

86-371-86003912

86-371-86003912